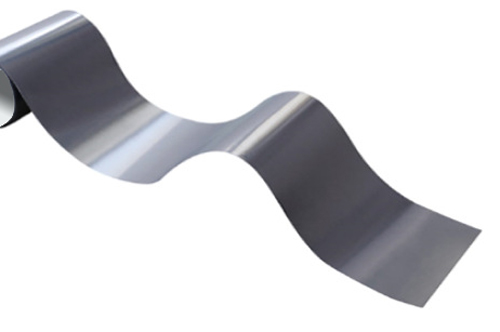

Thermally Conductive Material Graphite Sheet

Thermally Conductive Material Graphite Sheet, it is Thermal Interface Material, widely using by graphite pad, graphite pad is made by expandable graphite, expandable graphite is nature graphite.

Sungran has special production technology that can produce graphite paper as thin as 17 nm to 100nm.

Flexible graphite paper, grafoil, well know by Heat-dissipating graphite film is a very thin GTS, heat-conducting material with comprehensive properties, also known as thermally conductive graphite film, thermally conductive graphite sheet, graphite heat sink, etc., which provides the possibility for the thinner development of electronic products. The heat-dissipating graphite film has good reworkability. It can be compounded or glued with other film materials such as PET according to the application. This material is flexible, can be cut and punched into any shape, and can be bent multiple times; it is suitable for point heat sources The rapid heat conduction converted into a surface heat source has high thermal conductivity and is made of a highly oriented graphite polymer film. In addition to traditional methods, heat-dissipating graphite film is an ideal material to provide heat dissipation management/power device heat dissipation in a limited area or to provide auxiliary power device heat dissipation.

Characteristics

1. Excellent thermal conductivity: 350-550 w/(m-k)

2. Specific gravity: 1.5-1.9 g/cm3

3. Soft and easy to cut (can be bent repeatedly)

4. Low thermal resistance

5. Thickness 0.03 – 0.1mm

Application

Thermal graphite film is widely used in PDP, LCD TV, Notebook PC, UMPC, Flat Panel Display, MPU, Projector, Power Supply, LED, MID, mobile phone; DVD; digital camera; computer and peripheral equipment; sensor; semiconductor production equipment ; Optical fiber communication equipment and other electronic products!

Data

|

Test Item

|

Unit

|

Value

|

|

|

Color

|

Visual

|

Black

|

|

|

Material

|

Flexible Graphite

|

||

|

Thickness

|

ASTM D374

|

Mm

|

0.03-0.1

|

|

Specific Gravity

|

ASTM D792

|

g/cm

|

1.5-1.8

|

|

Continuous use Temp

|

EN344

|

℃

|

-40~+400

|

|

Tensil Strength

|

ASTM F-152

|

4900kpa

|

715PS

|

|

Volume Resistivity

|

ASTM D257

|

Ω/CM

|

3.0*10

|

|

Hardness

|

ASTM D2240

|

Shore A

|

>80

|

|

Flame Rating

|

UL 94

|

V-0

|

|

|

Conductivity(vertical direction)

|

ASTM D5470

|

w/m-k

|

25

|

|

Conductivity(horizontal direction)

|

ASTM D5470

|

w/m-k

|

300-5500 |

graphite film china